We are proud to produce and offer high-quality aggregates sustainably sourced from our own quarries. Whether it's sand, gravel, pebbles, or rock, everything that leaves our quarries meets the highest industry standards and is configured to meet and exceed industry standards and practices. Moreover, we can tailor our products to optimally meet individual customer requirements with expert consultation every step of the way. We collaborate e.g. with laboratories, universities, research institutes, designers, and engineering offices in all of our markets.

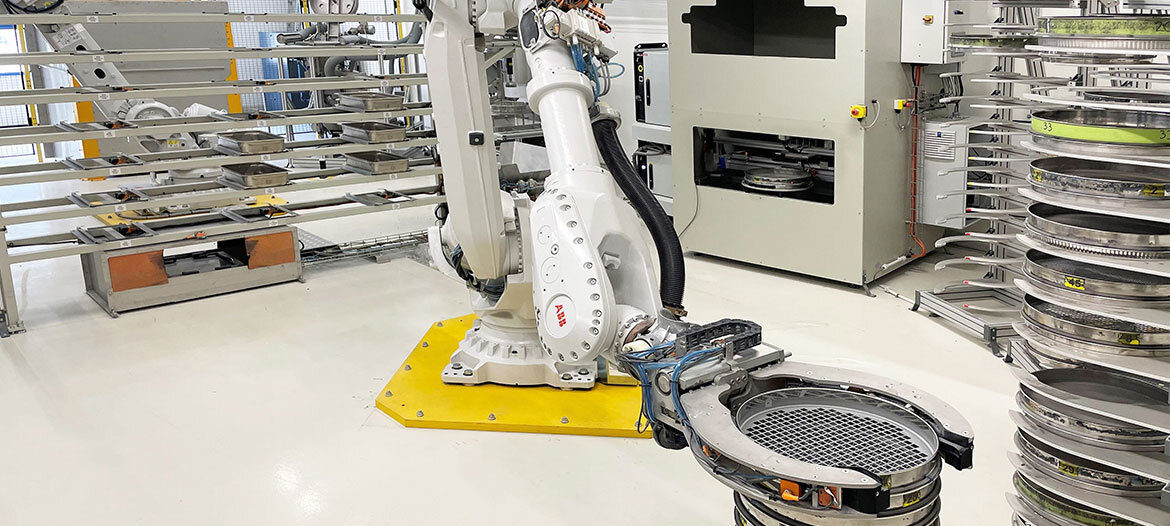

A game-changing automated lab

The latest processing technology is as important as quality and sustainability. That's why we operate a fully automated laboratory that is perhaps the most advanced in the world. Inside, we test, analyse, and rate our products before they leave our grounds. This ensures the exceptionally high quality and performance standards our customers expect from the Mibau Stema Group and from ourselves.

Every day, we focus our core business on meeting European and country-specific standards and specifications. Our team is well-versed in navigating diverse regulatory landscapes, ensuring seamless compliance with country-specific standards wherever our products are utilized.

We look forward to helping you get all your projects underway and laying the foundation for your further success.

Complete asphalt solutions driven by excellence

Aggregates for asphalt according to DIN EN 13043

- Asphalt and surface treatments for roads, airfields, and other traffic areas

- 95 % of all paved roads have an asphalt surface course

- Fulfills the highest requirements for skid resistance, impact resistance, and grain conformity

- High resistance to frost, freeze-thaw, and heat

- High availability and just-in-time delivery make us a reliable supplier, especially for large-scale projects.

- Security of supply in all asphalt grain sizes

Highway engineers and road designers worldwide know and appreciate asphalt's diversity and use as a paving material. With our product solutions, they can rely on high-quality asphalt that provides optimal cost-effectiveness, long-lasting durability, safety, and comfort for all their paving projects. Here are just a few of the attributes of our asphalt solutions that make it World-Class.

Aggregates for concrete DIN EN 12620

- Fulfils the highest requirements for water absorption, resistance to frost, freeze-thaw and impact crushing

- Harmless to alkali reactions

- "Load-bearing capacity plus durability" leads to a wide range of applications in building construction and civil engineering, concrete road construction, bridge construction, as a base in airfield construction, and more

Our application product range at a glance

Asphalt

- Sand and crushed sand

- Gravel and fine chippings

- Whitening stone

Concrete

- Sand and crushed sand

- Gravel and fine chippings

- Heavy aggregate

Railway construction

- Gravel blends

- Railway ballast

- Shoulder ballast

Road construction and ground surfacing

- Frost protection layer

- Gravel base course

- Paving chippings

- Binder-free surfacing

- Verge material

Asphalt

Asphalt

Aggregates for asphalt supplied from either Tau or our Jelsa Quarry

Concrete

Aggregates for infrastructure project (concrete) supplied from our Jelsa quarry.

Concrete

Railway construction

Railway construction

Railway Ballast material is supplied from the Tau quarry, and sub-layers from either Tau or Jelsa quarry.

Surface

Subbase delivered from Jelsa, Tau or our Dirdal quarry.